A Facility for Injection Mold Testing

and Pilot Runs to High Volume Production

MTMD is a precision Injection Molding facility located in St. Petersburg, Florida. Technology changes rapidly in our industry and MTMD found that embracing the newest technology helps ensure our customers’ success. MTMD is on your team from concept through creation with Engineering Services, Production Experience and Quality Support to see your project through.

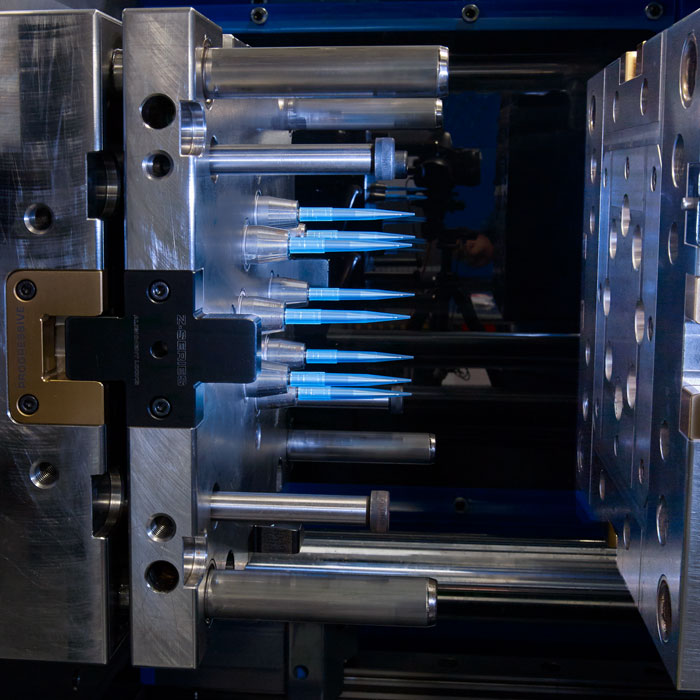

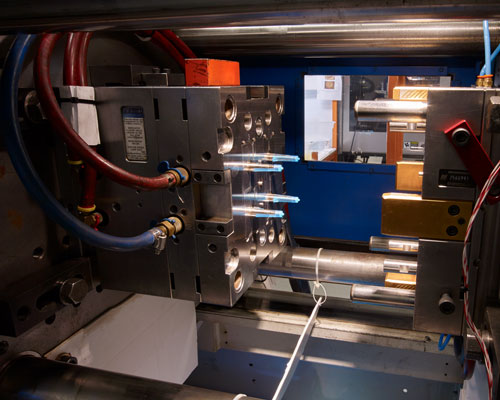

MTMD has the molding capability from 75 – 500 ton and can meet your molding needs from pilot to full production runs.

Our Facility

Our 22,000 sq ft controlled environment is equipped with the tools to meet your manufacturing needs, from concept to full production.

With our Molding floor, in a 22,000 square foot controlled environment, we have the capability to meet your project needs from prototype to full production. In our additional manufacturing areas, we can offer secondary services for our molded products from assembly to decorating and printing. MTMD’s success comes from investing in the latest technology for Engineering, Molding and Quality Services.

Our 22,000 sq ft controlled environment is equipped with the tools to meet your manufacturing needs, from concept to full production.

With our Molding floor, in a 22,000 square foot controlled environment, we have the capability to meet your project needs from prototype to full production. In our additional manufacturing areas, we can offer secondary services for our molded products from assembly to decorating and printing. MTMD’s success comes from investing in the latest technology for Engineering, Molding and Quality Services.

What we can do for you

Services

Quality

Quality Support

At MTMD, our certification to ISO 9001:2015 demonstrates our commitment to maintain and continuously improve our Quality Management System.

Our “state of the art” measuring capability ensures accuracy to the tightest tolerances.

Quality reporting can include anything from part dimensional inspection (in-process and pre-ship) to complete “First Article Inspection” (FAI). Our validation and qualification capabilities range from writing IQ, OQ, PQ protocols, mold validation, to six sigma statistical analysis and reporting. Our FAT/SAT protocols guarantee our equipment delivers virtually defect free components repeatedly.

Internal audits of our products and services assure compliance to our QMS, International standards and exceeding customer requirements.

At MTMD, our certification to ISO 9001:2015 demonstrates our commitment to maintain and continuously improve our Quality Management System.

Our “state of the art” measuring capability ensures accuracy to the tightest tolerances.

Quality reporting can include anything from part dimensional inspection (in-process and pre-ship) to complete “First Article Inspection” (FAI). Our validation and qualification capabilities range from writing IQ, OQ, PQ protocols, mold validation, to six sigma statistical analysis and reporting. Our FAT/SAT protocols guarantee our equipment delivers virtually defect free components repeatedly.

Internal audits of our products and services assure compliance to our QMS, International standards and exceeding customer requirements.

Engineering Solutions

One Source Strategy

MTMD works in conjunction with our customers on resin choice, the right technology and options for a successful project.

Because your success is our success, we emphasize the importance of R&D and offer the option of pre-production molds in the manufacturing process to save you time and money, while proving out your ideas. High collaboration with our customers during this step allows us to evaluate the product before development of a high-cavitation production mold.

Teaming with support from our parent company, Cavaform, our engineering teams’ combined experience allows us to support the evolving needs of the industries we serve. During the design phase of the process, we concentrate on achieving optimum manufacturing cost and timing solutions through a wide variety of mold technologies. The customer collaboration includes assistance with material selection and manufacturing options. This early collaboration can significantly reduce time and related costs by reducing the product development cycle.

Mold Test and Optimization

MTMD can perform full process development services for your existing molds or new ones. Focusing on key parameters and identifying factors for repeatability and process stability, ensures consistency in molding. These services can be provided in conjunction with our Quality group with dimensional reporting and validations. Process optimization is the best means to achieve the best cycle time reduction and repeatability.

Turn-key Validated Projects

Bring us your ideas and challenges and let our team design and deliver a running and completely validated molding work cell in your facility or leave it in ours for production.

Markets

Our History

MTMD was founded in 2008 as a mold testing and qualification facility for parent mold-making company, Cavaform International, LLC. Almost immediately, we saw the opportunity to serve customers in research and development, prototyping, and full production runs. We believe in onshoring and we take pride in our ability provide full art-to-part service at our facility in St. Petersburg, Florida, giving our customers the opportunity to keep production in the United States.

Our History

MTMD was founded in 2008 as a mold testing and qualification facility for parent mold-making company, Cavaform International, LLC. Almost immediately, we saw the opportunity to serve customers in research and development, prototyping, and full production runs. We believe in onshoring and we take pride in our ability provide full art-to-part service at our facility in St. Petersburg, Florida, giving our customers the opportunity to keep production in the United States.